REVIEW: PRODUKSI, KARAKTERISASI DAN APLIKASI SELULOSA BAKTERI DI BIDANG FARMASI

Abstract

Selulosa bakteri merupakan polimer yang memiliki aplikasi yang luas dan menjanjikan dalam berbagai bidang medis. Tujuan dari penelitian tinjauan pustaka ini adalah untuk melakukan penelusuran pustaka untuk mengetahui apakah substrat dan kondisi fermentasi mempengaruhi kualitas selulosa yang dihasilkan dan penggunaannya di bidang farmasi. Metode pengumpulan data yang digunakan adalah dengan melakukan studi kepustakaan dengan menggunakan kata kunci pencarian: produksi dan aplikasi selulosa bakteri. Artikel ini diulas dalam 10 tahun terakhir yang membahas tentang produksi, karakterisasi, dan aplikasi selulosa bakteri dalam bidang farmasi. Artikel tersebut didapat dari berbagai penelitian yang telah dilakukan melalui mesin pencari seperti Google Scholar, PubMed, dan Science Direct. Berbagai penelitian menunjukkan bahwa substrat, konsentrasi starter, suhu, pH, waktu fermentasi dan proses pemurnian sangat mempengaruhi kualitas selulosa yang dihasilkan. Studi karakterisasi yang dilakukan meliputi SEM, TGA, kadar air dan sifat mekanik. Dalam aplikasi farmasi, selulosa bakteri dapat digunakan untuk membuat pembalut luka, pembawa obat, dan bahan masker wajah, serta stabilisator emulsi dan rekayasa jaringan.

References

Al-shamary, E.E., Darwash, A.K.A.-, 2013. Influence of Fermentation Condition and Alkali Treatment on the Porosity and Thickness of Bacterial Cellulose Membranes. Tojsat 3, 194–203.

Aulia, N., Nurwantoro, Susanti, S., Rizqiati, H., Abduh, S.B.M., 2020. Pengaruh Periode Fermentasi terhadap Karakteristik Fisik, Kimia dan Hedonik Nata Sari Jambu Biji Merah 4, 131–136.

Badshah, M., Ullah, H., Khan, A.R., Khan, S., Park, J.K., Khan, T., 2018. Surface modification and evaluation of bacterial cellulose for drug delivery. Int. J. Biol. Macromol. 113, 526–533. https://doi.org/10.1016/j.ijbiomac.2018.02.135

Badshah, M., Ullah, H., Khan, S.A., Park, J.K., Khan, T., 2017. Preparation, characterization and in-vitro evaluation of bacterial cellulose matrices for oral drug delivery. Cellulose 24, 5041–5052. https://doi.org/10.1007/s10570-017-1474-8

Bao, L., Hong, F.F., Li, G., Hu, G., Chen, L., 2021. Implantation of air-dried bacterial nanocellulose conduits in a small-caliber vascular prosthesis rabbit model. Mater. Sci. Eng. C 122, 111922. https://doi.org/10.1016/j.msec.2021.111922

Boni, B.O.O., Lamboni, L., Bakadia, B.M., Hussein, S.A., Yang, G., 2020. Combining Silk Sericin and Surface Micropatterns in Bacterial Cellulose Dressings to Control Fibrosis and Enhance Wound Healing. Eng. Sci. 68–77. https://doi.org/10.30919/es8d906

Das, S. and Dash, H. R. (2020) Microbial and Natural Macromolecules: Synthesis and Applications - Google Buku, Elsevier. Available at: https://books.google.co.id/books?id=E9PVDwAAQBAJ&pg=PA313&lpg=PA313&dq=production+of+nanocellulose+bacteria+and+utilization+in+the+pharmaceutical+sector&source=bl&ots=I-GFY3vjxo&sig=ACfU3U03E4--64ji00d-h6-GbhTeyQVTaQ&hl=id&sa=X&ved=2ahUKEwi77KHcxs7tAhU1H7 (Accessed: 18 January 2021).

Gupta, A., Keddie, D.J., Kannappan, V., Gibson, H., Khalil, I.R., Kowalczuk, M., Martin, C., Shuai, X., Radecka, I., 2019. Production and characterisation of bacterial cellulose hydrogels loaded with curcumin encapsulated in cyclodextrins as wound dressings. Eur. Polym. J. 118, 437–450. https://doi.org/10.1016/j.eurpolymj.2019.06.018

Hamad, A., Handayani, N.A., Puspawiningtyas, E., 2014. Pengaruh Umur Starter Acetobacter xylinum Terhadap Produksi Nata De Coco ( Effects of the Starter Age of Acetobacter xylinum on the Nata de coco production ). Techno 15, 37–49.

Iskandar, Zaki, M., Mulyati, S., Fathanah, U., Sari, I., Juchairawati, 2010. Pembuatan Film Selulosa dari Nata de Pina. J. Rekayasa Kim. Lingkung. 7, 105–111.

Izzati, N., Irfan, I., Rohaya, S., 2019. Variasi Penggunaan Jenis Bahan Baku (Air Cucian Beras dan Air Kelapa) dengan Penambahan Ekstrak Tauge Terhadap Rendemen dan Mutu Nata. J. Ilm. Mhs. Pertan. 4, 300–307. https://doi.org/10.17969/jimfp.v4i2.10923

Jia, Y., Wang, X., Huo, M., Zhai, X., Li, F., Zhong, C., 2017. Preparation and characterization of a novel bacterial cellulose/chitosan bio-hydrogel. Nanomater. Nanotechnol. 7, 1–8. https://doi.org/10.1177/1847980417707172

Jia, Y., Zhai, X., Fu, W., Liu, Y., Li, F., Zhong, C., 2016. Surfactant-free emulsions stabilized by tempo-oxidized bacterial cellulose. Carbohydr. Polym. 151, 907–915. https://doi.org/10.1016/j.carbpol.2016.05.099

Jozala, A.F., Pértile, R.A.N., dos Santos, C.A., de Carvalho Santos-Ebinuma, V., Seckler, M.M., Gama, F.M., Pessoa, A., 2015. Bacterial cellulose production by Gluconacetobacter xylinus by employing alternative culture media. Appl. Microbiol. Biotechnol. 99, 1181–1190. https://doi.org/10.1007/s00253-014-6232-3

Junaidi, Z., Azlan, N.M., 2012. Optimization of Bacterial Cellulose Production from Pineapple Waste: Effect of Temperature, pH and Concentration. 5th Eng. Conf. "Engineering Towar. Chang. - Empower. Green Solut. 1–7.

Khusna, A., Prastujati, A., Setiadevi, S., Hilmi, M., 2020. Effect of starter sources and old fermentation on making nata de whey towards chemical quality. E3S Web Conf. 142, 1–5. https://doi.org/10.1051/e3sconf/202014204001

Krasteva, P.V., Bernal-Bayard, J., Travier, L., Martin, F.A., Kaminski, P.A., Karimova, G., Fronzes, R., Ghigo, J.M., 2017. Insights into the structure and assembly of a bacterial cellulose secretion system. Nat. Commun. 8, 25–28. https://doi.org/10.1038/s41467-017-01523-2

Latumahina, M., Awan, A., Rumahlatu, D., 2017. Pengaruh Suhu dan Lama Fermentasi Terhadap Uji Organoleptik Pada Pembuatan Nata Buah Enau (Areng pinnata Merr). Biopendix J. Biol. Pendidik. dan Terap. 4, 29–37. https://doi.org/10.30598/biopendixvol4issue1page29-37

Luo, M.T., Zhao, C., Huang, C., Chen, X.F., Huang, Q.L., Qi, G.X., Tian, L.L., Xiong, L., Li, H.L., Chen, X. De, 2017. Efficient Using Durian Shell Hydrolysate as Low-Cost Substrate for Bacterial Cellulose Production by Gluconacetobacter xylinus. Indian J. Microbiol. 57, 393–399. https://doi.org/10.1007/s12088-017-0681-1

Ma’ruf, M.T., 2018. Fiksasi Tulang Dengan Alat Berbahan Dasar Polimer (Uji Biokompatibilitas). Interdental J. Kedokt. Gigi 14, 27–31. https://doi.org/10.46862/interdental.v14i2.371

Malmir, S., Karbalaei, A., Pourmadadi, M., Hamedi, J., Yazdian, F., Navaee, M., 2020. Antibacterial properties of a bacterial cellulose CQD-TiO2 nanocomposite. Carbohydr. Polym. 234, 115835. https://doi.org/10.1016/j.carbpol.2020.115835

Mani, A. (2018) ‘Food Preservation by Fermentation and Fermented Food Products’, International Journal of Academic Research & Development, (1), pp. 51–57.

Marlinda, Hartati, R., 2019. Optimalisasi Karakteristik Nata De Banana Skin Melalui Perubahan. J. Optim. 5, 52–59.

Mohammadkazemi, F., Azin, M., Ashori, A., 2015. Production of bacterial cellulose using different carbon sources and culture media. Carbohydr. Polym. 117, 518–523. https://doi.org/10.1016/j.carbpol.2014.10.008

Mondal, I.H., 2015. Cellulose and Cellulose Composites Modification, Characterization And Applications. Nova Science, New York.

Muhajir, M., Suryanto, H., Larasati, A., 2018. Struktur dan Sifat Mekanik Film Bacterial Cellulose dengan Disintegrasi Mekanis. JPSE (Journal Phys. Sci. Eng. 3, 55–62. https://doi.org/10.17977/um024v3i22018p055

Muhsinin, S., Putri, N.T., Ziska, R., Jafar, G., 2017. Bacterial cellulose from fermented banana peels (Musa paradisiaca) by Acetobacter xylinum as matrix of biocellulose mask. J. Pharm. Sci. Res. 9, 159–162.

Nining, S.A., 2019. Pengaruh Derajat Keasaman (pH) dan Konsentrasi Bakteri Acetobacter xylinum terhadap kualitas Nata De Pina. Naskah Publikasi Universitas Muhammadiyah Surakarta.

Novikov, I. V., Pigaleva, M.A., Naumkin, A. V., Badun, G.A., Levin, E.E., Kharitonova, E.P., Gromovykh, T.I., Gallyamov, M.O., 2021. Green approach for fabrication of bacterial cellulose-chitosan composites in the solutions of carbonic acid under high pressure CO2. Carbohydr. Polym. 258, 117614. https://doi.org/10.1016/j.carbpol.2021.117614

Novita, R., Hamzah, F., Restuhadi, F., 2016. Optimization of the Concentration of Sucrose and. Jom Faperta 3, 1–14.

Pacheco, G., de Mello, C.V., Chiari-Andréo, B.G., Isaac, V.L.B., Ribeiro, S.J.L., Pecoraro, É., Trovatti, E., 2017. Bacterial cellulose skin masks—Properties and sensory tests. J. Cosmet. Dermatol. 17, 840–847. https://doi.org/10.1111/jocd.12441

Pertiwi, R. D. et al. (2018) ‘Pembuatan, Karakterisasi dan Uji In Vitro Nanopartikel Emas Berbasis Konjugat Gom Arab-Vinkristin’, Jurnal Ilmu Kefarmasian Indonesia, 16(1), p. 6. doi: 10.35814/jifi.v16i1.486.

Perugini, P., Bleve, M., Cortinovis, F., Colpani, A., 2018. Biocellulose masks as delivery systems: A novel methodological approach to assure quality and safety. Cosmetics 5. https://doi.org/10.3390/cosmetics5040066

Potivara, K., Phisalaphong, M., 2019. Development and characterization of bacterial cellulose reinforced with natural rubber. Materials (Basel). 12. https://doi.org/10.3390/ma12142323

Qiu, Y., Qiu, L., Cui, J., Wei, Q., 2016. Bacterial cellulose and bacterial cellulose-vaccarin membranes for wound healing. Mater. Sci. Eng. C 59, 303–309. https://doi.org/10.1016/j.msec.2015.10.016

Rohaeti, E., Laksono FX, E.W., Rakhmawati, A., 2016. Kemudahan Biodegradasi Selulosa Bakteri dari Limbah Cucian Beras dengan Penambahan Gliserol, Kitosan, dan Nanopartikel Perak. J. Kim. Val. 2, 35–44. https://doi.org/10.15408/jkv.v2i1.3083

Rose, D., Ardiningsih, P., Idiawati, N., 2018. Karakteristik Nata de Jackfruit (Artocarpus heterophyllus) Dengan Variasi Konsentrasi Starter Acetobacter xylinum. J. Kim. Khatulistiwa 7, 1–7.

Shao, W., Liu, H., Wang, S., Wu, J., Huang, M., Min, H., Liu, X., 2016. Controlled release and antibacterial activity of tetracycline hydrochloride-loaded bacterial cellulose composite membranes. Carbohydr. Polym. 145, 114–120. https://doi.org/10.1016/j.carbpol.2016.02.065

Sharma, C., Bhardwaj, N.K., 2019. Biotransformation of fermented black tea into bacterial nanocellulose via symbiotic interplay of microorganisms. Int. J. Biol. Macromol. 132, 166–177. https://doi.org/10.1016/j.ijbiomac.2019.03.202

Shimpi, N.G., 2018. Biodegradableing and Biocompatible Polymer Composites Process, Properties and Applications. Woodhead Publishing.

Shobib, A., Fatarina, E., Prasetiyo, J.A., 2019. Making Nata De Cassava From Rengginang Liquid Waste Using Acetobacter Xylium. Neo Tek. 5, 2–7. https://doi.org/10.37760/neoteknika.v5i2.1426

Suripto, P, U.S., Agustina, L., 2018. Identifikasi Mutu Pasca Panen Nata De Coco Berdasarkan Lama Perendaman Dan Perebusan. Inov. Agroindustri 1, 29–37.

Sutrisno, T.A., Suryanto, H., Wulandari, R., Muhajir, M., Zahari, S.M.S.N.S., 2019. The Effect of Chemical Pretreatment Process on Mechanical Properties and Porosity of Cellulose Bacterial Film. J. Mech. Eng. Sci. Technol. 3, 8–17. https://doi.org/10.17977/um016v3i12019p008

Ullah, H., Badshah, M., Mäkilä, E., Salonen, J., Shahbazi, M.A., Santos, H.A., Khan, T., 2017. Fabrication, characterization and evaluation of bacterial cellulose-based capsule shells for oral drug delivery. Cellulose 24, 1445–1454. https://doi.org/10.1007/s10570-017-1202-4

Vasconcelos, N.F., Feitosa, J.P.A., da Gama, F.M.P., Morais, J.P.S., Andrade, F.K., de Souza Filho, M. de S.M., Rosa, M. de F., 2017. Bacterial cellulose nanocrystals produced under different hydrolysis conditions: Properties and morphological features. Carbohydr. Polym. 155, 425–431. https://doi.org/10.1016/j.carbpol.2016.08.090

Volova, T.G., Prudnikova, S. V., Sukovatyi, A.G., Shishatskaya, E.I., 2018. Production and properties of bacterial cellulose by the strain Komagataeibacter xylinus B-12068. Appl. Microbiol. Biotechnol. 102, 7417–7428. https://doi.org/10.1007/s00253-018-9198-8

Wahid, F., Hu, X.H., Chu, L.Q., Jia, S.R., Xie, Y.Y., Zhong, C., 2019. Development of bacterial cellulose/chitosan based semi-interpenetrating hydrogels with improved mechanical and antibacterial properties. Int. J. Biol. Macromol. 122, 380–387. https://doi.org/10.1016/j.ijbiomac.2018.10.105

Wardhana, E., Rusmarilin, H., Yusraini, E., 2016. The Effect of Concentration of Sugar and pH on the Quality of Nata de Yammy from Yam Starch Waste Liquid. J. Rekayasa pangan dan Pert. 4, 323–331.

Wibowo, N.A., Isroi, 2015. Potensi In-Vivo Selulosa Bakterial Sebagai Nano-Filler Karet Elastomer Thermoplastics ( ETPS ). Perspektif 14, 103–112.

Yan, H., Chen, X., Song, H., Li, J., Feng, Y., Shi, Z., Wang, X., Lin, Q., 2017. Synthesis of bacterial cellulose and bacterial cellulose nanocrystals for their applications in the stabilization of olive oil pickering emulsion. Food Hydrocoll. 72, 127–135. https://doi.org/10.1016/j.foodhyd.2017.05.044

Yanti, N.A., Ahmad, S.W., Muhiddin, N.H., Ramadhan, L.O.A.N., Suriana, Walhidayah, T., 2021. Characterization of bacterial cellulose produced by acetobacter xylinum strain lkn6 using sago liquid waste as nutrient source. Pakistan J. Biol. Sci. 24, 335–344. https://doi.org/10.3923/pjbs.2021.335.344

Yanti, N.A., Isra, W.O., Parakkasi, V.N.R., 2020. Potensi Limbah Cair Tahu Sebagai Sumber Nitrogen Pada Produksi Selulosa Bakteri 5, 9–17.

Yasa, I.W.S., Basuki, E., Saloko, S., Handito, D., 2020. Sifat Fisik Dan Mekanis Lembaran Kering Selulosa Bakteri Berbahan Dasar Limbah Hasil Pertanian. J. Ilm. Rekayasa Pertan. dan Biosist. 8, 89–99. https://doi.org/10.29303/jrpb.v8i1.170

Ye, J., Zheng, S., Zhang, Z., Yang, F., Ma, K., Feng, Y., Zheng, J., Mao, D., Yang, X., 2019. Bacterial cellulose production by Acetobacter xylinum ATCC 23767 using tobacco waste extract as culture medium. Bioresour. Technol. 274, 518–524. https://doi.org/10.1016/j.biortech.2018.12.028

Zahan, K. A. et al.2015a. ‘Effect of Incubation Temperature on Growth of Acetobacter xylinum 0416 and Bacterial Cellulose Production’, Applied Mechanics and Materials, 815, pp. 3–8. doi: 10.4028/www.scientific.net/amm.815.3.

Zahan, K. A., Pa’e, N. and Muhamad, I. I. 2015b. ‘Monitoring the Effect of pH on Bacterial Cellulose Production and Acetobacter xylinum 0416 Growth in a Rotary Discs Reactor’, Arabian Journal for Science and Engineering, 40(7), pp. 1881–1885. doi: 10.1007/s13369-015-1712-z.

Zhang, Q., He, S., Zhu, X., Luo, H., Gama, M., Peng, M., Deng, X., Wan, Y., 2021. Heparinization and hybridization of electrospun tubular graft for improved endothelialization and anticoagulation. Mater. Sci. Eng. C 122, 111861. https://doi.org/10.1016/j.msec.2020.1118

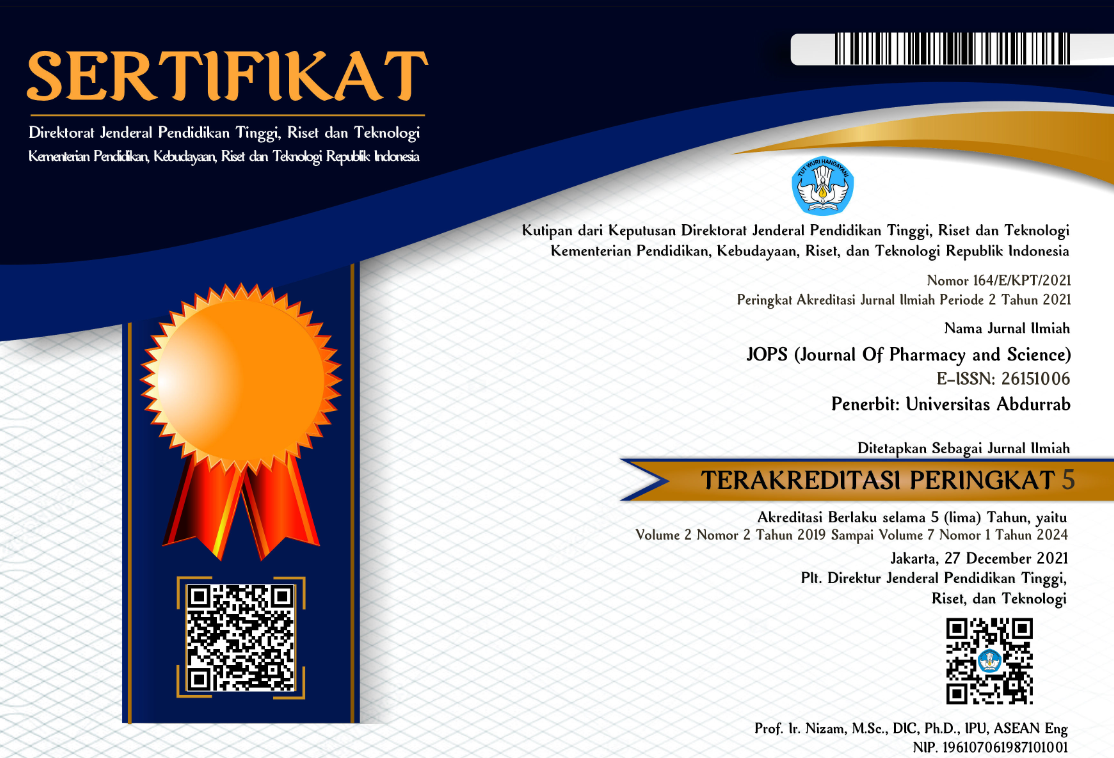

Copyright (c) 2021 JOPS (Journal Of Pharmacy and Science)

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

1. Copyright of all journal manuscripts is held by the JOPS (Journal Of Pharmacy and Science)

2. Formal legal provisions to access digital articles of electronic journal are subject to the provision of the Creative Commons Attribution-ShareAlike license (CC BY-NC-SA), which means that JOPS (Journal Of Pharmacy and Science) is rightful to keep, transfer media/format, manage in the form of databases, maintain, and publish articles.

3. Published manuscripts both printed and electronic are open access for educational, research, and library purposes. Additiponally, the editorial board is not responsible for any violations of copyright law.

licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

PDF

PDF

Abstract views: 1709

Abstract views: 1709

downloads: 2094

downloads: 2094

:

:

1.png)